Single Turning

When adopting the conveyor belt for the turning movement. the arc section of conveyor will joint with the straight conveyor and the both ends of the arc section should be guided to the straight, and then the conveyor will operate smoothly.

The inside radius requires at least 2.2 times the width of the conveyor belt .

STL1 ≧ 1.5 X W or STL1 ≧ 1000mm

Single turning does not limit to 90°; it has to obey the limitation of turning radius and make the design from 15°, 30°, 45°, 60°, 75°, 90°,.... to 360°.

Serial Turning

When adopting the conveyor belt for the turning movement. the arc section of conveyor will joint with the straight conveyor and the both ends of the arc section should be guided to the straight, and then the conveyor will operate smoothly. The length of straight operation requires 2times the width of the conveyor belt. For the serial turning motion , please do not design more than 4 turnings.

The inside radius requires at least 2.2 times the width of the conveyor belt .

STL1 ≧ 1.5 X W or STL1 ≧ 1000mm

STL2 ≧ 2 X W or STL2 ≧ 1500mm

Notes

When the conveyor operates, it will easy to make unusual noises due to the phenomenon of pausing and vibrating. The idler end of the belt could not move until there is enough tension to overcome the friction between the belt and the carry way. These noises can be eliminating by adopting the grease or soap liquid to lubricate hold down rails and wearstrips.

HONGSBELT serial turning belts, can be applied in the wet environment with high temperature, such as steam which temperature is 95°C. We recommend the inside radius should be more than 3 times the width of belt, and the angle of single or serial turning could not larger than 180°. We have lots of actual design and experience for your reference; please contact with our technique department or local agencies.

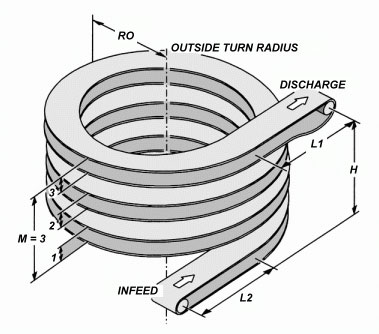

Spiral Conveyor

When the return type spiral conveyor which belt in return way is operating by the transporting way but in opposite direction is designed in serial turning and operated in the same direction, it will form the shape as a spiral curve. At the both ends of spiral turnings are also required to guide to the straight, and then it would operate. The minimum length of the straight should be at least 1.5 times belt width of the conveyor, and it could not shorter than 1000mm.

The inside radius of the spiral conveyor rotates in 360 degrees spiral; pay attention to the number of layers do not exceed over 3 layers, it also signified that total rotating angle of spiral conveyor could not exceed over 1080 degrees.

Notes for Spiral Conveyor

For the HONGSBELTserial turning belts, if the inner radius is over 2.5 times the width of belt , it will make unusual noises due to the phenomenon of pausing and vibrating. The idler end of the belt could not move until there is enough tension to overcome the friction between the belt and the carry way. These noises can be eliminating by adopting the grease or soap liquid to lubricate hold down rails and wearstrips.

Calculation Formula for Outside Radius of Spiral Conveyor

An illustrate below is the calculation formula for outside/inside radius of spiral conveyor belt system.

FORMULA:

Conveyor belt length = 2B+ ( sprocket diameter x 3.1416 )

A = D × 3.1416 × P ( X )

B = ( √ H2 + A2 ) + L1 + L2, B = A / Cos DEG. or B = H / Tan DEG.

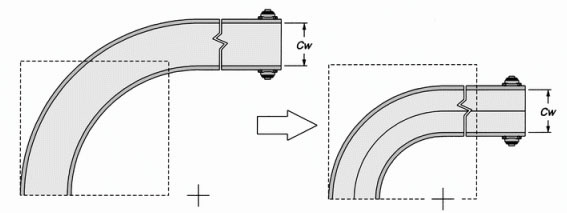

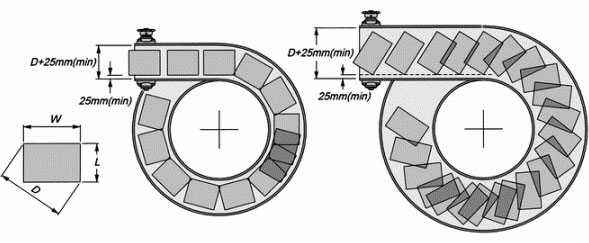

Reduce Inside Radius

There are several strict restrictions on inside radius of HONGSBELT turning belts. When designing and manufacturing turning belts, the space problem of factory will be encountered all the time. The factory is not able to accommodate the huge conveyor; it is necessary to narrow down the inside radius of belt. It may adopt two rows of belts or multi rows of belt design on the turning section to substitute for the single belt, to overcome the problem of excessive wide inside radius. However, this design may probably result in the speed of outside belt would slower than the inside belt. Please pay attention to if this will affect the efficiency of the conveyor system or not.

Design Example

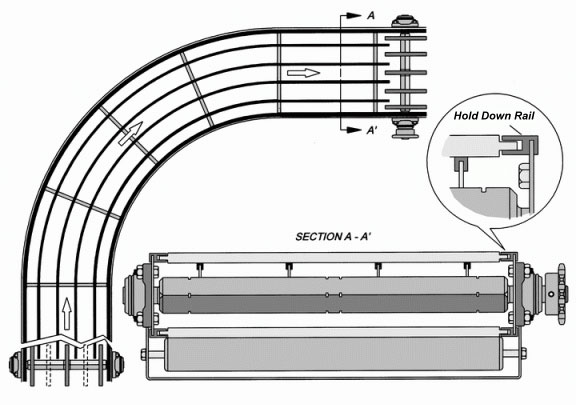

Example for Hold Down Rail Installation

Hold Down Rail are made by HDPE material. The installation of Hold Down Rail at C shape rabbet part must comply with the steel frame on the side of conveyor, follow along the radian and insert it, to complete the installation. For low temperature operating environment, it is available to use gas heater or electric air heater to heat it up to 100~120℃ and bend it in the appropriate shape to fit the installation required.

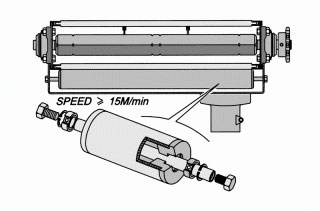

Operating Speed

The belt will have the condition of piling up in return way, and result in the belt pausing and vibrating. Therefore, when the operating speed is higher than 20M per minute, adopt ball bearing rollers to replace the hold down rails in the position of return way will solve the problem.

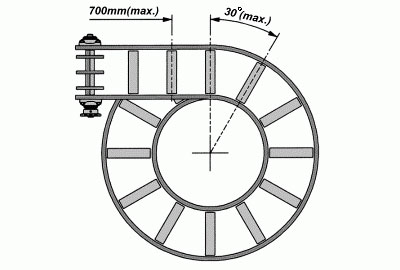

Interval Limitation of Return Way Roller

When turning conveyor belt system use ball bearing rollers to support the return way, the interval between rollers at straight section should be smaller than 650mm. The included angle at the turning section is no more than 30 degree or the length of outside curve is no more than 600mm, the average of the included angle. It will have more average contact area when the return way rollers support the belt. If the length of outside curve is more than 600 mm of the roller interval, it should install the supporting slide guide (UHMW) to assure the stability operatipn of the return way.

Notes for Belt Width

When products are loading on the carry way of turning conveyor system, they will follow the liner motion of the conveyor to move forward. Products do not rotate on the surface of the belt because of the linear speed of conveyor belt is in concert motion during transporting. Therefore, when design the conveyor belt system, the belt width should be larger than the maximum width of the carry product